Electronics manufacturing services (EMS) are critical to the development of mission-ready defense and aerospace technologies. These services encompass every stage of production, from PCB design and fabrication to component sourcing, assembly, testing, and ruggedization.

EMS providers work to ensure that military-grade electronics meet stringent ITAR, AS9100, ISO 9001, and MIL-STD-810 compliance requirements, guaranteeing durability and performance in extreme environments.

Defense and aerospace electronics must withstand temperature extremes, vibration, electromagnetic interference (EMI), and exposure to moisture or contaminants. Through rigorous quality assurance and failure analysis, EMS providers enhance product reliability for applications such as radar systems, avionics, satellite communications, and electronic warfare.

By incorporating rapid prototyping, obsolescence management, and embedded system integration, EMS plays a crucial role in advancing military technology and maintaining operational readiness.

Table of contents:

Comprehensive Electronics Manufacturing Services

EMS providers offer a full suite of services tailored to the unique demands of aerospace and defense manufacturing. These services ensure that electronic components are designed, tested, and assembled to withstand mission-critical operational conditions.

Design and Prototyping

The development of high-reliability PCBs for military and aerospace applications requires careful planning and testing. EMS providers specialize in:

Electronics Manufacturing Services by Offshore Electronics

- PCB design and fabrication – Creating custom printed circuit boards optimized for high-frequency signals, durability, and harsh conditions.

- Rapid prototyping – Accelerating the testing and validation of new electronics, reducing time to deployment.

- Reverse engineering – Reproducing obsolete components or redesigning systems to maintain compatibility with legacy platforms.

- 3D printing services – 3D printed enclosures and parts for prototype and custom electronics

Electronics Assembly and Production

EMS providers manufacture electronic components using advanced assembly techniques that meet military-grade standards for durability and reliability. Key services include:

- PCB assembly (PCBA) – Using surface-mount technology (SMT) and through-hole assembly (THA) to ensure high-quality, efficient board production.

- Cable and harness assembly – Custom wiring solutions for avionics, unmanned vehicles, and secure communications systems.

- Conformal coating and ruggedization – Protective coatings to shield electronics from moisture, dust, and corrosion.

Testing and Quality Assurance

To guarantee performance in military and aerospace environments, EMS providers conduct extensive testing and validation procedures:

- Failure analysis – Identifying weak points to enhance product durability.

- JTAG and boundary scan testing – Debugging and verifying PCB integrity.

- Thermal management solutions – Ensuring optimal heat dissipation for high-power military electronics.

- Environmental stress testing – Simulating extreme conditions to verify compliance with MIL-STD-810, MIL-STD-461, and MIL-STD-704.

Lifecycle Support and Obsolescence Management

Given the long service life of military and aerospace systems, EMS providers offer lifecycle management solutions to maintain and upgrade electronic components over time:

- Component sourcing – Ensuring the availability of critical parts despite supply chain challenges.

- Obsolescence management – Redesigning or sourcing alternative components for aging systems.

- Secure electronics recycling and refurbishment – Safeguarding sensitive military technology.

Industry Standards and Compliance

Electronics manufacturing for defense and aerospace must adhere to strict regulatory standards to ensure safety, security, and performance. EMS providers comply with:

- ITAR (International Traffic in Arms Regulations) – Controlling the export and handling of sensitive military technology.

- AS9100, AS9110, AS9120 – Aerospace industry quality management standards.

- ISO 9001, ISO 14001, ISO 27001 – Ensuring quality, environmental management, and data security.

- MIL-STD-810, MIL-STD-461, MIL-STD-704 – Defining environmental and electromagnetic compliance for rugged electronics.

- IPC-A-610, IPC J-STD-001, IPC-2221, IPC-6012 – Covering PCB assembly, fabrication, and soldering standards.

- DO-254, DO-178C, DO-160 – Governing safety and reliability for avionics systems and airborne electronics.

Key Applications of Defense and Aerospace EMS

Electronics manufacturing services support a range of mission-critical military and aerospace applications. These include:

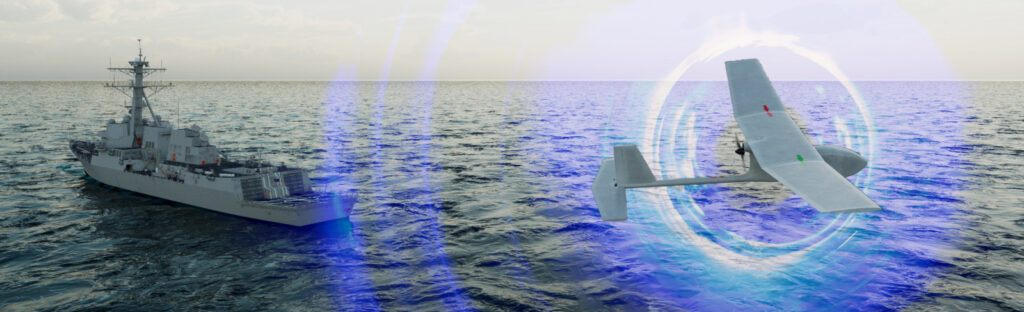

Unmanned Systems

Advanced EMS solutions power unmanned aerial vehicles (UAVs), unmanned underwater vehicles (UUVs), and unmanned ground vehicles (UGVs). These autonomous systems rely on high-performance embedded electronics, secure communications, and real-time processing for navigation, surveillance, and reconnaissance missions.

Radar and Electronic Warfare Systems

EMS providers design and manufacture radar systems, electronic countermeasures, and RF/microwave components for air defense, threat detection, and electronic warfare (EW). Signal processing hardware, antenna arrays, and secure encryption modules are essential for these applications.

Avionics and Satellite Communications

Reliable EMS solutions support flight control systems, cockpit displays, and mission computers in military aircraft and spacecraft. High-performance satellite communications and ground stations depend on precision-engineered electronics for secure data transmission and real-time battlefield awareness.

Military Robotics and Tactical Drones

EMS providers supply custom electronic enclosures, ruggedized processors, and embedded control systems for autonomous robotics, tactical drones, and mobile command centers. These technologies play a critical role in surveillance, explosive ordnance disposal (EOD), and reconnaissance.

Command and Control Systems

From secure battlefield networks to mobile command centers, EMS providers deliver secure communications solutions, rugged servers, and encryption hardware to ensure real-time command and control capabilities.

Advancing Military Electronics Manufacturing

The defense and aerospace industries rely on cutting-edge electronics manufacturing services to develop rugged, high-performance technology for mission-critical applications.

As threats evolve, EMS providers continue to innovate in areas such as thermal management, obsolescence mitigation, and secure embedded systems. By adhering to strict military standards and leveraging state-of-the-art manufacturing processes, electronics manufacturing service companies play a vital role in ensuring the reliability, security, and longevity of next-generation military and aerospace electronics.