Suppliers

Add your company

Cutting-Edge Electro-Mechanical Actuators for Military & Defense Applications

Cutting-Edge UAV Technologies for Defense Primes, Drone OEMs and Systems Integrators

If you design, build or supply Servo Motors, create a profile to showcase your capabilities on this page.

Products

Overview

Military servo motors play a crucial role in military and defense systems, providing precise control and positioning capabilities in challenging operational conditions.

These devices allow for very precise positioning of the motor’s output shaft, utilizing sensors such as potentiometers or absolute encoders to provide position feedback in order to achieve this. They may take analogue or digital control signals as inputs, and may be powered by AC or DC.

They can be classified into two basic types – rotary or linear:

- Rotary servo motors convert electrical energy to rotational motion and provide mechanical torque, and may rotate through a fixed angle or provide continuous rotation.

- Linear servo motors further convert the motor’s rotational motion to linear motion, and may utilize one of a number of mechanisms to do this, including rack and pinion, belt and pulleys, and ballscrew.

Military Servo Motor Applications

Thanks to their ability to deliver highly accurate control of position, as well as movement speed and torque, they are used widely for military and defense applications.

Land – They may be utilized in armored and land vehicles to control turrets and weapons platforms, providing precise aiming and targeting capabilities. They can also be found in military robotics, such as the arms of bomb disposal robots.

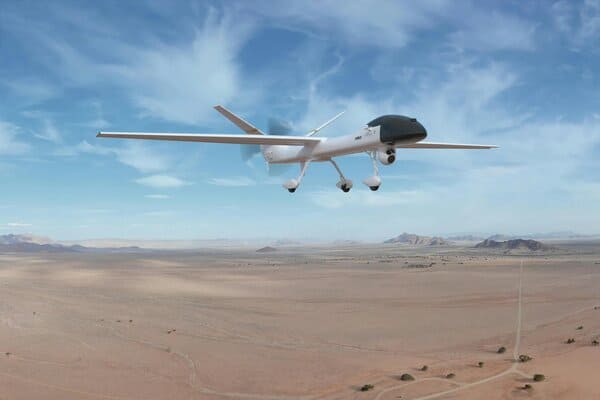

Air – Military- and aerospace-grade servo motors are also found in a wide variety of aircraft subsystems, including weapons systems and radar and antenna positioning mechanisms. They are also used for opening and closing doors and hatches, and for positioning flight control surfaces.

Sea – At sea they can be found in naval vessels, warships and submarines. They are used for rudder and fin control, sonar and radar positioning, door and missile hatch actuation, and ballast control systems. Subsea and marine servo motors may require additional ruggedization to resist saltwater corrosion, as well as to withstand greater pressures.

Rugged Servo Motor Drives

Typically designed to be ruggedized against shock and vibration, they may be housed in enclosures that feature enhanced ingress protection against water and dust. They may also include built-in cooling mechanisms to ensure that they do not overheat under prolonged usage or when operating in environments with extreme temperature variations.